The Resilience of Allco tanking membranes under extreme weather conditions

During the extreme weather events of early 2023, our tanking membranes were really put to the test. A lot of construction sites around the country were negatively affected by the intense rain events wreaking havoc on already tight schedules and causing large delays, not to mention the increased cost due to the loss of product and time to replace.

However, projects that utilised the robust and resilient Allco tanking membranes, while impacted by this unprecedented weather, were able to recover and get back on schedule quickly due to minimal remedial work being required.

Two large Auckland projects were impacted, Site 6 Wynyard Quarter and the ADHB Hospital Tunnel.

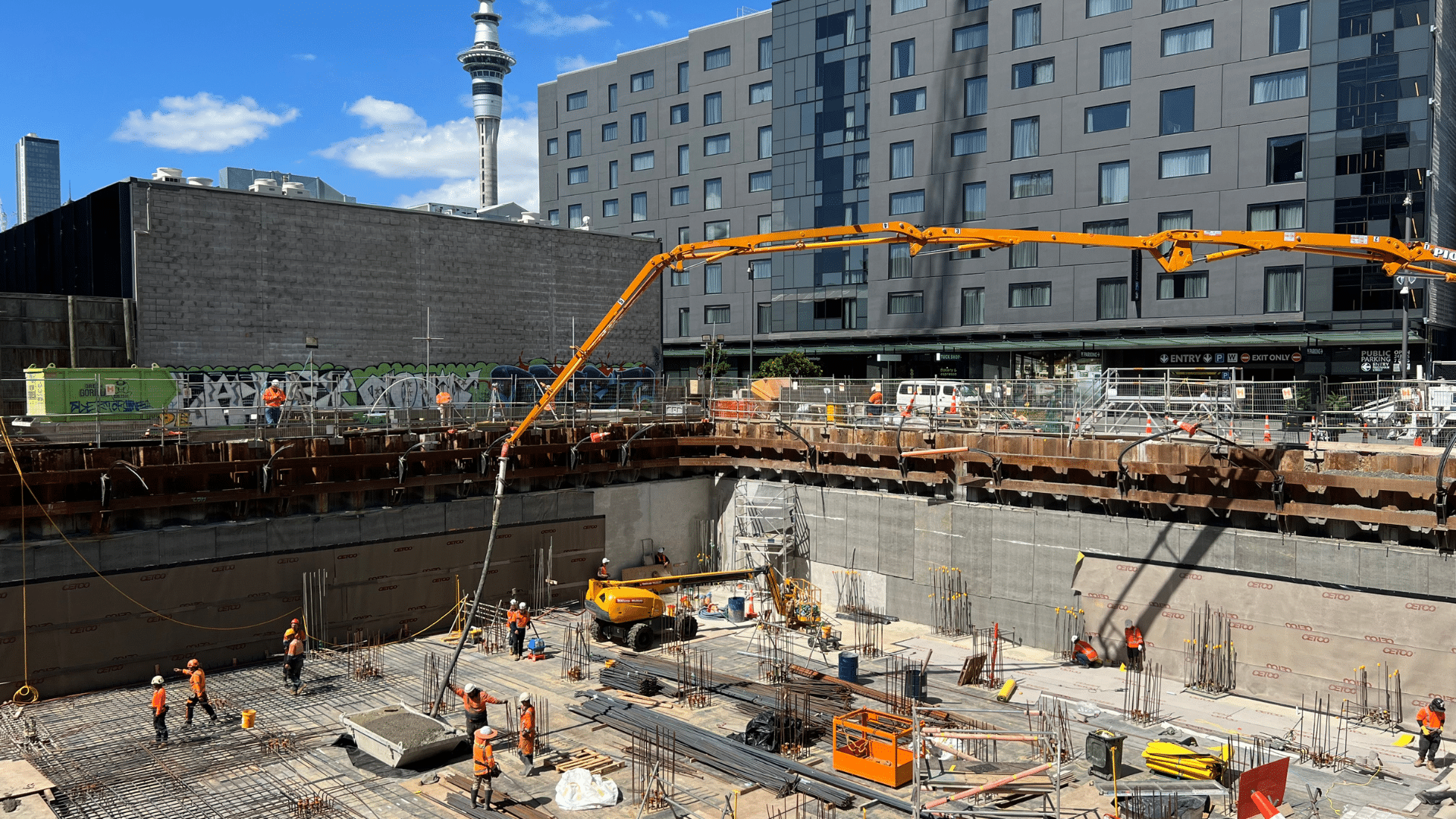

Site 6 Wynyard Quarter

The double basement excavation of Site 6 in Wynyard Quarter was flooded with over one million litres of stormwater in late January. This ponding took two days and 12 pumps working around the clock to clear. After most of this water was cleared, Adrian Crow, Senior Technical Advisor for Allco visited the site to complete an evaluation of the 5,000m2 of Coreflex membrane that had been installed a few months earlier.

The exposed membrane (under-slab application) had been completely submerged in the stormwater. Some hydration is acceptable within the membrane before concrete is placed and tests were conducted onsite to see the various hydration levels in the APC layer. The majority of locations were wet but not displaced, meaning only desiccation (drying) was required. Where desiccation was not an option an overlay of Coretex (APC layer) was installed to reinstate the compromised area.

The Coreflex membrane installed in the pit survived well due to being covered and all steel being fixed. Some reinforcing chairs needed re-positioning and final drying carried out.

One section of the wall collapsed due to the weight of the water sitting behind the unconfined membrane and ended up lying behind the already fixed steel. As a result, this was the largest section of remedial work required for the membrane.

All welded laps and remaining vertical applications were still intact ensuring no membrane required total replacement.

ADHB Hospital Tunnel

Also affected by this intense rain event was the construction site for the new Tunnel at the Auckland Hospital in Parnell.

The applied Volclay Voltex and Waterstop RX to the tunnel floor and walls was totally submerged in the deluge. 750 thousand litres of water had to be pumped out before an assessment of the damage could be completed.

Water was found behind the wall membrane which needed releasing and patching after the water was drained. An injection tube was added as an extra precaution however none of the membrane was lost or needed replacement.

Bentonite granules were added to help support the hydrated Waterstop RX and extra care was needed while placing the concrete but none of the Waterstop RX had to be replaced either.

These 2 projects highlight the remarkable resilience of our Allco tanking range under the most extreme conditions allowing these large and important projects to get back on track with minimal disruption and avoiding costly and time-consuming full membrane replacement.

Read more: Intense rain events, project design and water control post-construction – Explore the need for improved water control measures, in non-hydrostatic conditions, and emphasizes the importance of proactive approaches to mitigate potential damage.

If you have any questions or need technical support please get in touch with our technical team tech@allco.co.nz