Intense rain events, project design and water control post-construction

In light of the recent surge in intense rain events, which were once considered rare but are now becoming more frequent, it has become imperative to address the design considerations for below-ground structures. This article explores the need for improved water control measures, in non-hydrostatic conditions, and emphasizes the importance of proactive approaches to mitigate potential damage. By adopting a forward-thinking mindset and implementing robust backfill systems, we can prevent the compromising of tanking systems and ensure effective water management.

Understanding Backfilling Methods

In the context of water control, it is essential to recognize the two distinct methods of backfilling for hydrostatic and non-hydrostatic conditions. While the installation methodology of our Volclay Tanking System remains the same, the choice of backfilling method can vary based on specific project requirements. It is crucial to implement the appropriate method to ensure optimal water pressure management.

Non-Hydrostatic conditions

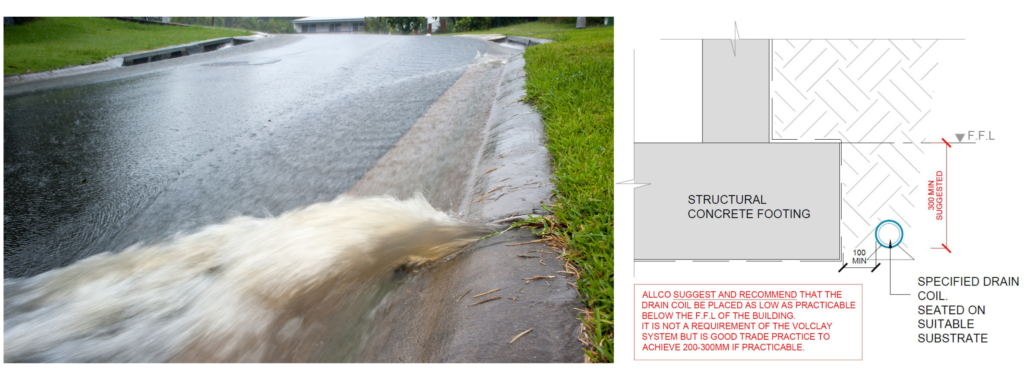

In scenarios where the tanking system is designed for non-hydrostatic conditions, a drain coil is typically placed at the base of the retaining wall. Coupled with suitable drainage materials as backfill, this design effectively directs water away from the retaining wall and towards the stormwater drains. These considerations are vital for preventing water build up and subsequent water damage.

Hydrostatic conditions

When the project has no water control, post-construction, the surrounding area becomes hydrostatic, exerting greater pressure on the tanked retaining walls. In such cases, a backfill design requires increased confinement pressure. For instance, the Volclay Tanking System recommends the use of gap 40 (or 60) with fines compacted every 300 to 400 mm, much like the design utilized for under slab or under roading or around lift pits.

Embracing a Forward-Thinking Approach

Due to recent rain events and the ongoing unpredictable weather patterns, prioritising water control measures in post-construction projects is crucial. Non-hydrostatic sites are particularly vulnerable as they have not been designed to cope with such extreme conditions. Adopting larger drain coils or multiple drain coils, placed further below the inside finished floor level, along with increased backfill volume, can effectively address challenges caused by temporary hydrostatic conditions, because of intense rain. By implementing a redesigned and more robust backfill system, allows sufficient time for water to escape to the stormwater drains, before building temporary hydrostatic conditions, potentially compromising the tanking system. It is time to shift our approach and proactively incorporate water control measures rather than attempting to rectify issues after the fact.

Regular Maintenance of Drains and Cesspits

To ensure unobstructed water flow to the stormwater system, it is essential to emphasise the regular inspection and maintenance of both residential and commercial drains and cesspits. By conducting periodic checks, potential blockages can be identified and promptly resolved, minimizing the risk of water build up and related complications.

Conclusion

The changing climate patterns require a revaluation of water control practices in construction projects. By prioritising effective water management from the design phase through to post-construction, we can mitigate the impact of intense rain events and prevent potential damage. Implementing improved backfilling techniques, utilizing larger (or more) drain coils positioned well below the finish floor level, a larger volume of backfill and performing regular maintenance are crucial steps toward a more resilient and sustainable approach to water control.

Read more: Tanking in Wet Conditions –Weather conditions can play a significant part in and can delay construction and have a lasting effect if the membrane selected requires special or unrealistic conditions during installation.

If you have any questions or need technical support please get in touch with our technical team tech@allco.co.nz